The humming never stops.

The printing press at the УлшжжБВЅ is always ready to go, says John Lundgren, director of print operations.

And it will continue humming until the end of June, but it wonтt be humming for the Star: On May 20, the paper transfers print operations to Phoenix. The Star churns out other publications, which will busy the press through June, when the humming stops completely.

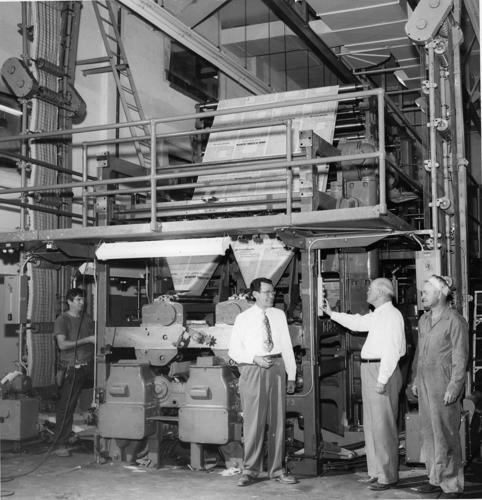

The mammoth Goss Metroliner offset press т it is three stories high, 175 feet long and weighs 1,000 tons (thatтs 2 million pounds) т was state-of-the-art when the Star purchased it in 1971.

And itтs still a wonder press, says Lundgren. тIt runs and runs,т he says. тItтs like a Mercedes. You can put miles and miles on it, and it keeps on going. It still produces high-quality papers.т

People are also reading…

But to keep that up, the press needs expensive upgrades. It makes more economic sense to print on a newer Goss press in Phoenix.

Itтs the end of an era. And sad for Lundgren.

тIтm definitely attached to it,т he says.

Before it goes away and becomes scrap metal, get to know the impressive machine that has printed the Star every day, save one, since Aug. 19, 1973.

In the beginning

The Star and УлшжжБВЅ Citizen were operating out of a crowded building in downtown УлшжжБВЅ when Michael Pulitzer, owner of the Star, and William A. Small Jr., who owned the Citizen, decided it was time for a new home.

Construction of a plant, which would house both papers and the print facilities, began in 1972 at South Park Avenue and East Irvington Road. The decision was also made to upgrade from the seven-unit letterpress in use to the 12-unit offset press, with each unit having its own printing capabilities. The quality is higher and the output greater with the offset presses.

Before the building was completely done, the press was moved, piece by piece, from Chicago, where it had been assembled, tested and dismantled.

Once here, construction continued around the press rooms while experts from Goss put it back together again, and retesting began. That took about a year, says Lundgren.

The first papers on the new press rolled out the night of Aug. 19, 1973; the next morning, the Star was on subscribersт doorsteps to read while they had their morning cup of joe.

A wonder

When the press is running, the metal stairs leading to each of the three floors vibrate, the smell of fresh ink fills the air, and the drums move at such a speed that it is shocking a wind isnтt created. The rumble fills the whole southwest side of the Starтs building.

On the the first floor, massive rolls of newsprint are loaded onto the press. As the press begins rolling, the roll starts to unwind, feeding paper to the press through slots in the two upper floors. It is slow at first but quickly picks up speed. When all the pages are printed, they are fed to what Lundgren calls тan engineering marvelт: the folder. Without slowing the press, the folder sorts pages, cuts them, and transfers the papers via a gripper conveyor to the mailroom/packaging center, where papers are bundled and readied for pickup by the carriers.

But before that happens, press operators lean over as the first papers come out on the conveyor belt, grab them off the folder and rifle through them to make sure ink is set and color is registering. It isnтt unusual for a slight adjustment to be made.

The day the press stopped

On July 22, 1982, a series of transformers that provided electricity to the building were damaged. While they were being inspected, there were several explosions. Seven people were injured, four of them seriously. One of them, Frank Delehanty, the Starтs business manager, eventually died from the burns to his body.

That day, reporters kept their mourning in check and furiously wrote stories, which were then flown to Phoenix and printed on the press at The Phoenix Gazette, which has since folded.

Technicians worked tirelessly, and the press was ready to go the next day.

Whoops

Lundgren, who started in the press room in 1976, leads the way to a room on the first floor.

тThis is the black ink room,т he explains.

At the far end are two massive tanks filled with black ink; each holds 6,000 gallons. Ink pump lines lead from the tanks to the press on the upper floors.

тNotice the stain on the floor here,т Lundgren says as he points to a cement floor that appears to be grayish black.

тTwo different times, these ink lines blew and filled this room with ink up to here.т He points to the wall above the floor board to indicate how high the ink flood was.

тThat was a nightmare.т

Another time, a roll of tape was put improperly on a hanger in the press. When the presses got up to speed, that steel hanger slipped off and was crushed under the cylinder.

тWe had to do a lot of work and money to repair the press,т Lundgren says as he points to the flattened hanger in a shadow box and hanging on his wall.

тThis is artwork,т he says with a smile.

There have been a few fires, as well.

Lundgren admits to being sentimental about the press. For 43 years, that familiar rumble and hum as paper meets ink has been the soundtrack of his career, and he admits he will miss it.

Lucky for him a stroll down memory lane is only 90 minutes away.

Contact reporter Kathleen Allen at kallen@tucson.com or 573-4128. On Twitter: @kallenStar

Itтs like a Mercedes. You can put miles and miles on it, and it keeps on going. It still produces high-quality papers.т John Lundgren, УлшжжБВЅ director of print operations

The people who print, package and transport newspapers at the УлшжжБВЅ

УлшжжБВЅ press, packaging, transportation employees

Jeff Aronhalt. Press Supervisor. 41 years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Debbie George. Packaging: Insert Loader. Forty years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Irma Camacho. Packaging: Inserter. Twenty-three years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

George Duarte. Transportation: CDL Driver. Thirteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Joanna Jacobs. Packaging: Forklift Driver. Thirty years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Steve Wood. Press Maintenance Technician. 10 years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Marco Fierro. Folder Operator. 35 years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Damian Nunez. Operations Electronic Specialist. 32 with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Nancy Loyola. Packaging Center Supervisor. 26 years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Roger Rinehart. Press Operator. Thirty-six years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Ariel Melena. Press Trainee. Four years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Kevin McCaffrey. Pressman. Thirteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Hector Alegria. Pressman. Nineteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Richard Buelna. Pressman. Twenty-four years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Gutberto Castelo. Pressman. Fourteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Temujin Gerritson. Pressman. Fourteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Chris Barrett. Press Supervisor. Eighteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Erik Vigil. Pressman. Two years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Mario Smith. Pressman. Seventeen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Benjamin Taylor. Press Supervisor. Seventeen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Kirk Molett. Warehouse Operator. Thirty-four years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Maricela Navarro. Lead Person: Packaging. Twenty years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Julio Rios. Transportation: Lead Driver. Twelve years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Kerry Vallen. Transportation: Lead Driver. Thirty-four years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Sherrie Holden. Packaging: Lead Line Person. Five years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Julia Espriu. Packaging: Lead Person. Twenty-one years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Leila Castillo. Packaging: Inserter. One year with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Oralia Garcia. Packaging: Inserter. Eighteen years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Jorge Gonzalez. Packaging: Inserter. Three years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Rudy Marquez. Packaging: Inserter. Twenty-seven years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Luis Balderrama. Packaging: DOT Driver. Eleven years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Hector Espriu. Packaging Center Technician II. Twenty years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Adam Fortado. Packaging: Machine Operator. Two years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Travis Salazar. Packaging: Inserter. Six years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Josh Cruikshank. Packaging: Inserter. Five years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Nathan Lamadrid. Packaging: Inserter. Three years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Cynthia Overton-Ellis. Packaging: Lead Person. Six years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Aaron Montiel. Packaging: Machine Operator. Four years with the УлшжжБВЅ.

УлшжжБВЅ press, packaging, transportation employees

Ted Furphy. Press Maintenance Technician. Twenty-one years with the УлшжжБВЅ.Т